Fit-for-purpose condensate extraction pump

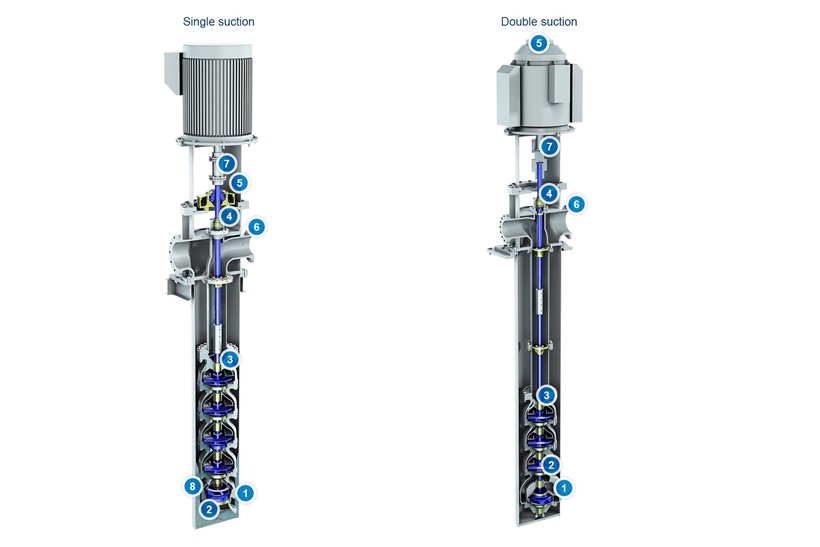

LTDN vertical can condensate extraction pumps, are specified wherever limited NPSH is available, either due to system constraints or liquids operating near to their vapor pressure, typically for condensate extraction and heater drain pump applications. NPSH requirements of the pump are met by simply adjusting the length of the pump and can, with the advantage of minimized floor space usage.

Carbon graphite product lubricated bearing in bowls and columns for long maintenance-free periods

Removable seal housing allows servicing of the throttle bushing without removing the head

Separate fabricated driver stand allows the use of one suction and discharge head per pump size

Spacer coupling allows servicing of the mechanical seal and thrust bearing as required

Lateral and anti-rotational ribs provide uniform inlet velocity along the can length

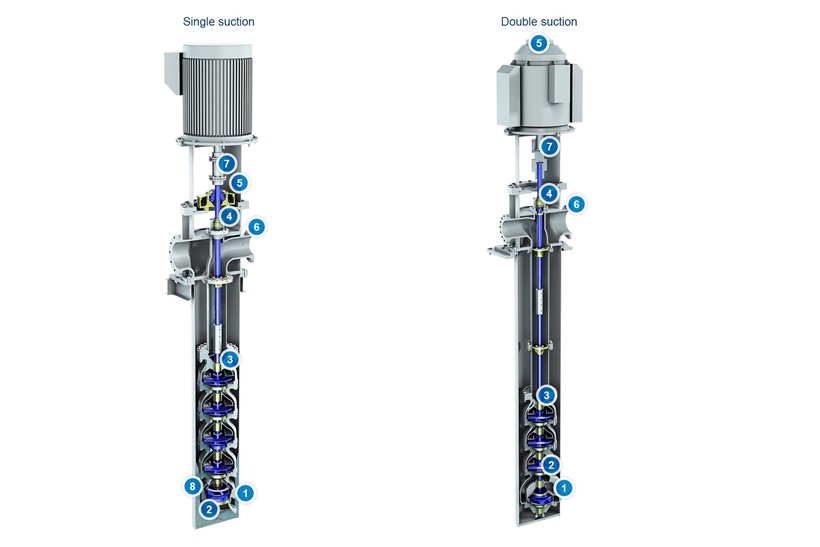

The LTDN pumps are vertically suspended, double-casing, bowl diffuser pumps specially designed for condensate extraction and heater drain pump in:

1. Single suction high Nss (suction specific speed) or double suction low Nss first stage

Reduced net positive suction head required (NPSHR)

2. Replaceable wear ring surface for impellers and bowls

Allows conservation of the running clearances

3. Carbon graphite product lubricated bearing in bowls and columns

Long maintenance-free periods

4. Shaft sealing by single or double mechanical seal with removable seal housing

Allows servicing throttle bushing without removing the head

5. Axial thrust bearing in pump or in motor

Adaptable to IEC or NEMA motors

6. Cast or fabricated suction and discharge head with separate fabricated driver stand

Allows using one suction and discharge head per pump size

7. Space coupling

Allows servicing the mechanical seal and thrust bearings as needed

8. Provided with lateral and anti-rotational ribs

Uniform inlet velocity along the can length

Introduction

Introduction PRODUCT CLASSIFICATION

PRODUCT CLASSIFICATION Article

Article

Previous:

Previous: Back to product list

Back to product list

Xiangyin Industrial Park, Jinlong Town, Xiangyin County, Hunan Province, China

Xiangyin Industrial Park, Jinlong Town, Xiangyin County, Hunan Province, China susie@hnljpump.com

susie@hnljpump.com